Jet Process Corporation

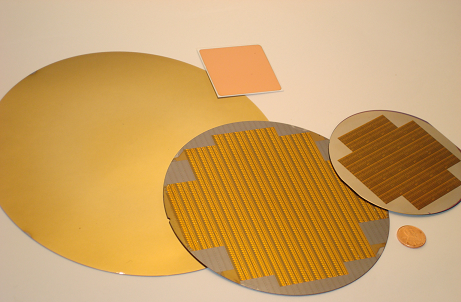

Specialists in Thin Film Solder Coatings & Other Advanced Thin Films for High Tech Applications

Thin film metal deposition service based on proprietary Jet Vapor Deposition™ (JVD™) process

JVD™ enables innovative and otherwise unavailable thin film solutions for advanced technology applications. JVD's low temperature, low vacuum operating conditions provide high rate deposition, high utilization of source material, and is a clean, environmentally sound operation that offers many advantages over conventional thin film metalizing techniques.